Expanding the boundary of traditional crafts The challenges of Edo Kiriko store "Hanashyo" incorporating ideas of different industries seamlessly

Expanding the boundary of traditional crafts The challenges of Edo Kiriko store "Hanashyo" incorporating ideas of different industries seamlessly

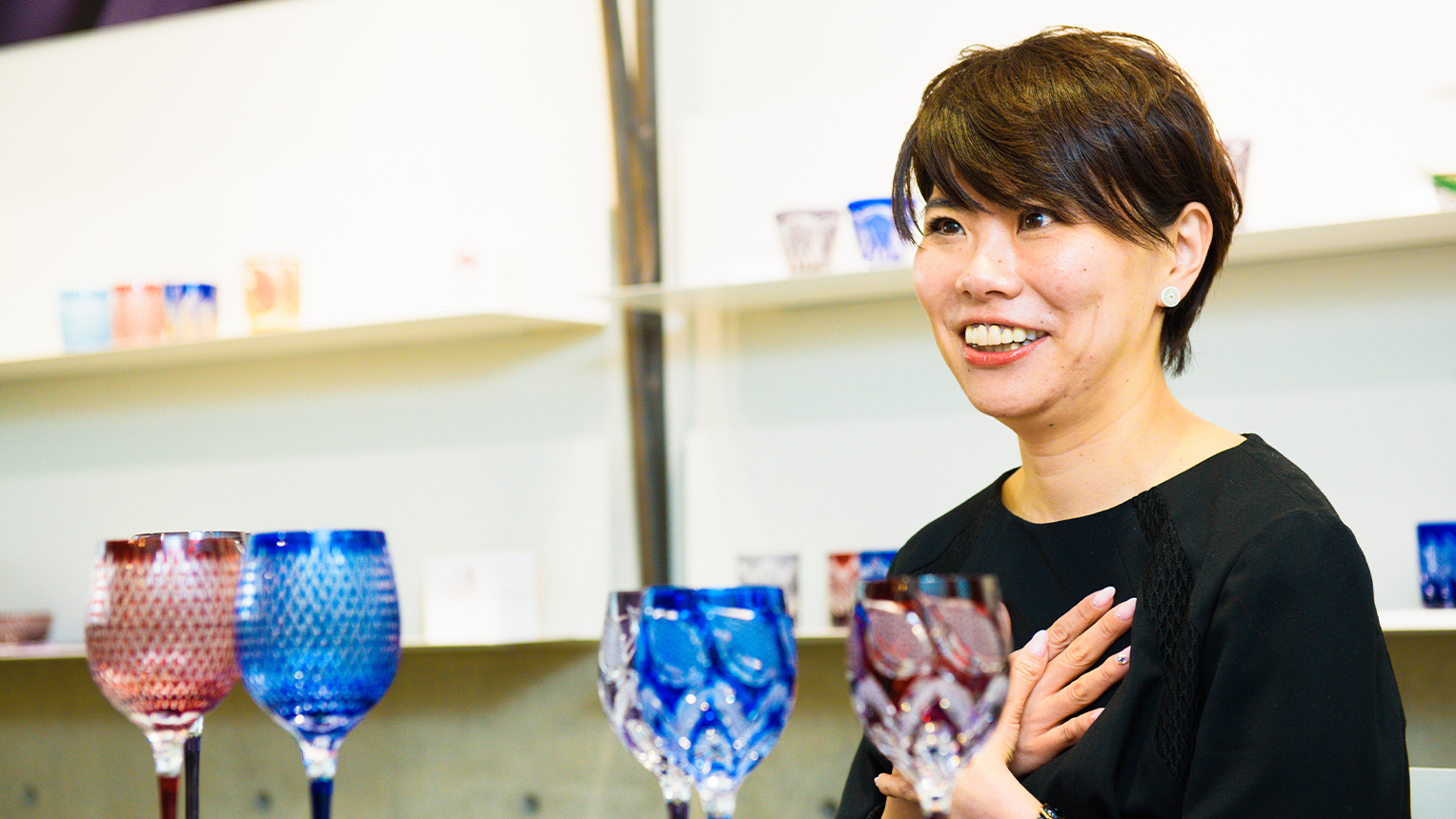

Everyone is familiar with the beautiful craft known as Edo Kiriko. Despite the fact that "Edo" was in its name, there was no studio in Nihonbashi which was its birthplace. A Hanashyo Nihonbashi store opened and changed the scene in 2016. Its company actively promotes the culture of "MADE IN TOKYO" and expands the boundaries of the traditional crafts We interviewed the store manager, Chisato Kumakura.

Starting from a living room. Their craftsmanship with the hospitality of a service industry.

―Please tell us about the journey of Hanashyo.

The founder, my grandfather, was a disciple of glass atelier in the Koto district. After that, he became independent and opened his own business in Kameido in 1946, which was the start of Hanashyo. The Nihonbashi store is new, just opened in 2016. We handle many works by Takayuki Kumakura who is my younger brother and a craftsman. It is a company that has been mainly managed by a family over three generations.

―Why did you decide to open the second store in Nihonbashi?

The birthplace of Edo Kiriko is said to be Nihonbashi Odenmacho, but there was no workshop. I have been talking for over 10 years that I would like to have a store in Nihonbashi someday because we are about Edo Kiriko. I encountered a good property when the timing was right with funds and a production system so I opened the store.

―I can see that it was a long-awaited open. I heard that you used to make products from a manufacturer in the past.

My grandfather used to manufacture ordered materials as a subcontractor of a major glass maker and received the processing fees. This was a common practice in Edo Kiriko's workshops, but my father who was a second-generation seemed to have doubts about making only what was ordered because his company had the technology and experience beyond that. So, he made his own original work during his free time and gave them to his friends. Over time, the products became popular, and more and more people wanted to spend money to buy them, and they began to sell as well.

―It sounds like a side business approach.

Yes, my father approached like that at first. But more people said they wanted to buy and some of them were corporations, so it seemed possible to sell them without manufacturers in between. So, they courageously stopped being a subcontractor and focused on direct sales.

At first, they were selling the products for the living room table ("kotatsu") in the house. When someone came over, they put out the work and put it back as they went away, eating food on the same table (laughs). The current Kameido store is a renovation of the living room table.

―That means the first store started from a living room table (kotatsu)...! I like that you are close to the customers.

We are close for sure. With direct sales, we can listen to a customer's needs one by one. This is our marketing strategy. Since we value the happiness of our customers, we are more like a service industry than a workshop. As we want to keep this stance, we are committed to direct sales and no wholesale.

Career choices, the family business.

―How did you, Ms. Kumakura, joined the business?

I was originally a school teacher. However, I was a non-regular worker so my employment was not stable, and I was wondering what I should do with my career. When I asked my parents what I should do, they told me to join their company and I decided to enter the family business. So, I was not originally aiming for this business... so I guess this is not a good example (laughs).

―Not at all, I can relate better (laughs). Were you not interested in the family business?

Honestly, I did not like it very much. My parents worked 24 hours every day doing everything from manufacturing, packaging and delivery when I was a little kid. They did not get weekends. Watching them work, I preferred a 9-5 job (laughs).

―You seem very active now. What was the reason for your change of mind?

There was not a clear turning point, but I had experience in teaching and I liked to tell a story to people. I feel that my thoughts on my work have changed since I was asked to speak at a seminar because of that. I learned that what I have done so far is useful for the family business.

After that, I met many people outside the company through my work, and learned about various business. It became more and more fun. I began to feel that such encounters and learning have only happened because of the family business. I started to love my job.

―That is a wonderful change. The world expanding due to your career choice.

At first, I did not have high aspirations, but now I am proud to be involved in the traditional culture as a Japanese person. I feel good that I am responsible for the future of traditional crafts and being able to have dreams.

The atmosphere is like a university seminar. The members come from different backgrounds ranging from engineer to bartender.

―There are many young people in Hanashyo, including Mr. Kumakura. This is a rare case because I always hear about the aging of craftsmen being a problem.

Now there are a total of 12 employees, including craftsmen, sales and planning, but it is certainly young because there are many members in their 20s. They are all inexperienced employees who have learned our craftsmanship and technology from the beginning. Many have changed their jobs, ranging from a system engineer to bartender.

―A former system engineer… That is a very different job.

I agree. As our age group of the current members is young, the threshold seems to be low for the same generation, and since the information in the workshop is openly shared, there is a large amount of information that is available before entering the company. Maybe that is why it is easy for young people from other industries to challenge in our business. Also, thanks to the fact that I often appear in the media, we might be well known among other workshops in the same business.

―What are the attractions they find after entering the company?

Many employees feel that it is worthwhile to make something with their own hands and make people happy. The atmosphere of the company is as friendly as the university seminar, and the scale of 12 people is just good enough and comfortable to work. Employees who used to have a hard time working at a company works lively in my company, and one time I received a call from their parents and they said, "Thank you for making my child lively!" (Laughs)

Learning from Apple and Baccarat. Going beyond the framework of traditional crafts to global brands.

―The employees often share stories on the blogs. I felt something like a sense of mission to convey the Edo Kiriko.

I'm just doing what a normal company would do. But traditional craft industry is not good at sharing their stories online so it may seem rare. First of all, Edo Kiriko is a dish and daily necessities, and they are good for gifts as well as everyday use, so I would like people to use the products in a carefree manner. I want to tell people that they are welcomed to visit the store anytime. So that is why I share my stories online frequently and try to reduce the psychological distance between Edo Kiriko and our customers.

―I see. Do you have a strategy with conveying the openness?

Well, I read books and so on to learn branding for large companies. For example, I really like Apple's idea of cherishing both technology and design. I actively share what I learned from outside sources in my company.

―Apple! I did not expect that. That is a completely different industry.

If we look at it in the framework of "traditional crafts," it will be hard to develop. There are cases like Baccarat which is a traditional craft but developed as a global brand. By actively taking information from such companies, we are conscious of sharing the ideas in-house as easy-to-understand cases. What we are doing should be the same as Baccarat, but in Japan, a traditional craft industry tends to be closed.

―Certainly, I do not receive a closed impression from Baccarat. The business is likely to expand if Japanese traditional crafts are considered The same industry as Baccarat.

Yes. We want to do our best to do our business openly.

This Edo Kiriko product is made by hand from beginning to end, and the resulting glow is made possible by their direct sales strategy.

―I would like to ask you about the product in detail. What is the commitment of Hanashyo to Edo Kiriko?

First of all, we have superior craftsmanship. You can't make good products without good craftsmanship, so that's the foundation. Our second generation learned it from their parents and developed into the original pattern that they created. We aim for the craftsmanship that conserves tradition with contemporary design.

―Is it unusual to do everything from the beginning to the final finish by hand in your business?

It is. Edo Kiriko originally lays over a colored glass over white glass and cuts it with a machine called a grinder. If you cut it, it will become frosted glass, so you have to polish it to make it glow. They are usually immersed in chemicals to make the glass glow, but we do not use any chemicals. We do everything by hand from the beginning to the final polish of the process. We take time to polish the patterns one by one. The resulting appearance looks different like this.

Examples of the products finished with chemicals versus those of Hanashyo

―I can see a big difference in the way they shine even with my amateur eyes!

When the chemicals are used, the color fades and the light becomes dull. If you touch it again, you may find that the hand-polished product is more solid and the cut contrast is visible.

―Yes, the touch is different as well. The details of the pattern have come out clearly as well.

The hand-polished products are also durable enough to be washable with a scrub. Also, a shallow and delicate cut in the surface will be visible because the glass is not weakened by chemicals.

However, the reason we can hand-polish without relying on chemicals is that we only make a limited number via direct sales. It's impossible to do everything by hand if it's made in large quantities, so it is an important part of our company made possible with our sales strategy.

The collaboration leading to new products' motifs. Incorporating ideas from different industries.

―Recently, you have been active in collaborating with other industries. This washcloth (tenugui) with the Edo Kiriko motif is wonderful.

Thank you. When I first decided to make this, my parents were worried that I was making a washcloth, but once it was made, it turned out very good. The experience made me realize that the role of our generation in Hanashyo is to expand the world of Edo Kiriko.

Example of a collaboration product

―How did this collaboration happen?

A company making a washcloth called "Todaya" in Nihonbashi suggested collaborating with them through our mutual friend. I requested in a casual manner, and their proposal was wonderful. Everyone was excited about the novel design combining several patterns. We thought it was very cool. By the way... from this collaboration, we also came up with a new Edo Kiriko design in which the two patterns were combined.

―So, the collaboration with a company making washcloth lead to the new design of Hanashyo?

Yes. The idea developed and turned into three types of products (glass, plate, and vase). When I collaborate, I intentionally do not to give any requests. By doing so, we encounter unexpected proposals that are not in our idea range, and it leads us to upgrade our products. It is very interesting and we learn a lot.

A product originating from washcloth design

―So, the developing process is fun.

It led to a collaboration with the well-known shops of Nihonbashi. For example, we collaborated with Mr. Haibara who makes a traditional one-stroke letter paper, a small letter set (binsen), and Mr. Ibasen who makes a traditional hand-fan (sensu). These ideas were developed from being introducing by friends. Nihonbashi is a city that connects people, so it's a lot of fun.

Plus, everything is faster since I came here. Maybe it is Edo's temperament. If I request something they finish the next day. If I plan a meal with a few months in advance, they reply that they are available next week (laughs). The speed allows things to proceed forward. I secretly call Nihonbashi “the city of speed and ideas."

Endless ideas - collaboration with overseas in mind.

―What do you want to challenge next?

I would like to further promote the "usage" of Edo Kiriko. Right now, I'm mainly focused on selling products, but I would like everyone to know how they can be used by promoting the beauty of the glass when pouring sake. For example, we are thinking of holding seminars at night or collaborating with hotels and have our products used in bars.

―With the Olympic Games happening next year, you may have more chances to promote.

Kyoto still has a strong presence, but Tokyo has a surprisingly large amount of traditional crafts. I would like the foreigners who are familiar with Tokyo to know the city's products "MADE IN TOKYO."

I'm also interested in collaborating with overseas. A design pattern of product is an expression of culture, so it is likely that interesting design will be created if the different cultures are combined. My employees have voiced that they want to make the product with glass from overseas, and I wonder what happens when the different pattern and color are incorporated.

―If that is realized, Japanese traditional crafts will be interesting even more.

I always have things I want to do, but we want to cherish our stance of "the service industry using Edo Kiriko," and advance so that more people will enjoy our products.

Interview by Minako Ushida (Konel), Photos by Daisuke Okamura

Hanashyo

Address : 3-6-5 Nihonbashi-honcho, Chuo-ward, Tokyo, 103-0023

Phone number : 03-6661-2781

Business hours : 10:30 - 18:00 (11:30〜17:00 on Saturday, Sunday and Holidays)

No scheduled holidays

.jpg)