Cars Evolve by Raw Materials. The Future of Automobiles through Collaboration with Toray Technology.

Cars Evolve by Raw Materials. The Future of Automobiles through Collaboration with Toray Technology.

How many of you know about the enormous contributions made by the technology of Toray, a material manufacturer, while in midst of the automobile industry going through what has been called a period of evolution happening once every 100 years? Today, we visited Mr. Motohito Tanaka, section manager of the Automotive Material Strategic Planning Department (at the time of interview), who is in charge of this field that is gaining wide attention. In this interview we asked about various insights by Mr. Tanaka, from how “communicating” the technology is just as important as developing highly functional materials to update automobiles, to the trials and errors, and future challenges.

Being a jetsetter, became an Expert on Automotive Materials.

-First of all Mr. Tanaka, please tell us about your career so far.

partment that was completely technology-oriented called the ”Plastic Technology Department.” Later I became in charge of sales for plastic, and have been involved with automotive plastics to this day. Toray’s salesperson is not only involved in direct sales activities, but also in the business development. I was in charge of visiting our main clients who were automotive component manufacturers to showcase technologies such as highly functional plastics, all the while listening to their needs to tie it into the next development.

-So you entered the company more or so for clerical office work, but ended up working in pretty technology-oriented area.

I was what you would call a literature-oriented student, and definitely did not like math or physics (laughs). So in my first year at the Plastic Technology Dept., I had absolutely no understanding of chemical formulas and was like “Oh my God what am I doing in this department....” But thanks to my senior colleagues who taught me things and having studied on my own, my knowledge gradually improved to where I am able to have a general understanding in all fields of this company now.

-After gaining experience in sales, what have you been involved in?

After handling sales in various domestic regions, I applied and was accepted in an in-house recruitment for overseas training program for young employees. Upon studying English for several months, I interned at “Toray Resin Co.” a subsidiary located in Michigan, USA that handles plastic resin related products, where I ended up being employed and stayed there for a total of 7 and a half years. Back then I was in charge of handling Japanese manufacturers such as Toyota. Later I worked in China such as Suzhou, Guangzhou, Shanghai and Hong Kong, and returned to Tokyo in 2016 to my current job today. It’s almost 20 years since I last worked in Nihonbashi, so I was shocked how the town changed. I was like, “What on earth is this and where am I?!” (laughs).

-You literally traveled the world. We understand that your main work involves automotive plastic resin. Would you tell us examples of how Toray materials are specifically used?

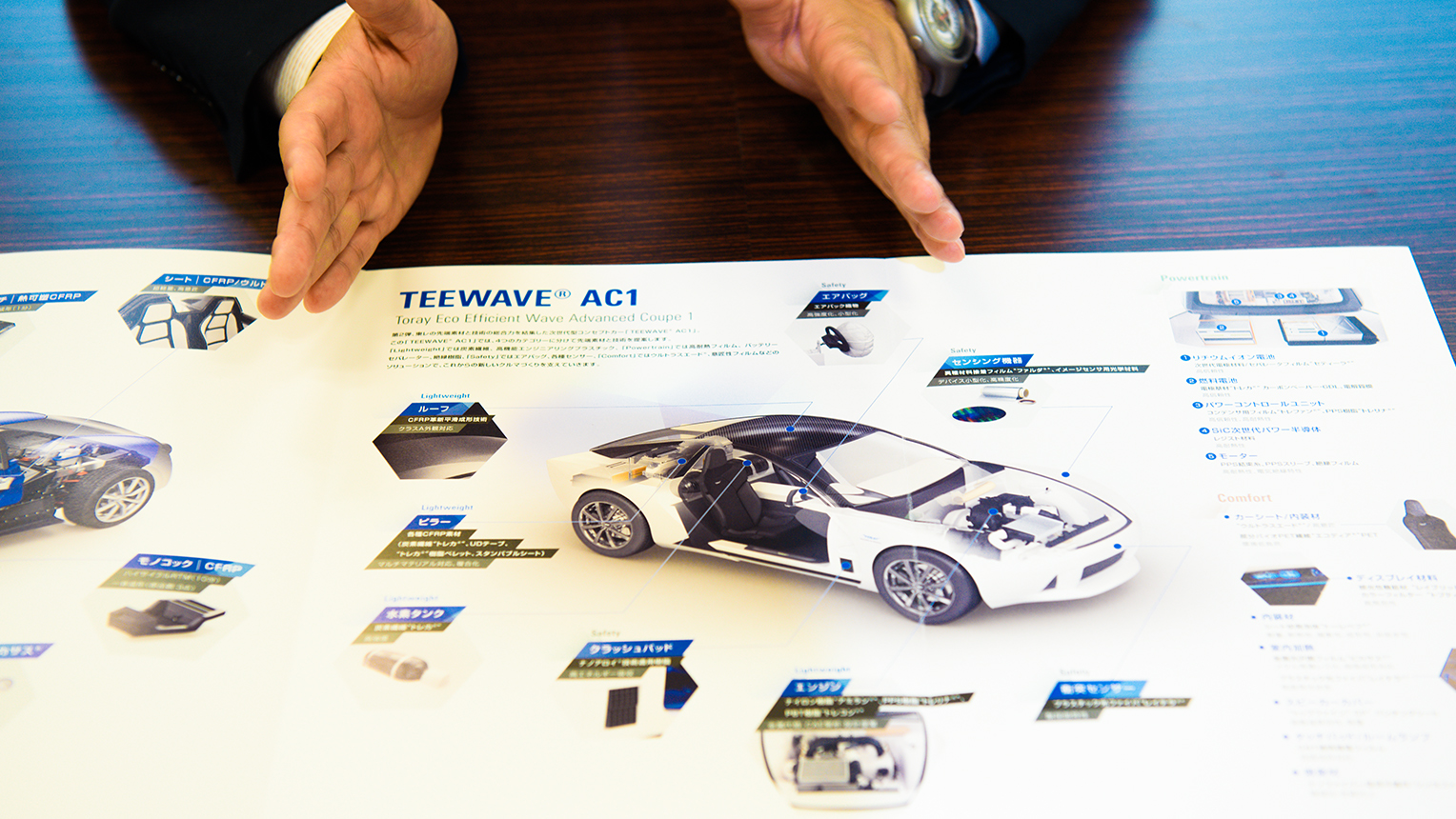

They are used in numerous areas. First of all, in order to improve fuel efficiency by reducing the weight of automobiles for CO2 reduction and improving the performance of power trains (general drive systems) in electric automobiles, a highly functional material that is light, durable and safe that can replace conventional metal is indispensable. In this field, many of Toray’s materials such as carbon fibers and engineering plastics, etc. have been contributing. In addition to reducing the weight, we can provide materials for airbag textiles using the fiber technology required in car safety, materials for collision sensors and displays required for the electric wiring in cars, acoustic absorbers that improve in-car comfort, etc. As you can see from these functionalities of the materials and real-life applicationexamples, we have even built a concept car called the TEEWAVE AC1.

Pamphlet for the TEEWAVE AC1. Various Toray technologies are packed into this single car

Introduction Video of “AUTOMOTIVE SOLUTIONS,” Toray’s automotive-related business

-A material that can structure one, whole entire car...Toray seems to have a wide range of materials and technologies.

The research and development that Toray has continued to work on in our 100 year of history over a wide range of fields are what has lead to this much range of our products. Out of which, we have gained considerable attention towards our carbon fiber composite materials that could substantially reduce the weight of a car. However, the amount of time required to build this material and its high manufacturing costs are the issues as to why the pricing has not been lowered. In addition, recent trends in this industry tend to shift for cost-cutting, therefore just being great material does not me it will be widely available. In essence, just being lightweight is not enough. It will not be accepted in the market unless you add value by combining with another technology, such as reducing vibrations. That is a tough issue.

-Are there any ideas to provide additional value for the market?

Each department is constantly working everyday to add more value, but another way of looking is to build the market itself. This example may seem a little extreme, but although just being lightweight won’t add value, if we propose a “flying car,” then things become a little different. Since weight reduction holds much significance in the aerospace industry, adding the fact that Toray had long been a material provider of airplanes, if we can come up with a new market by means of cars x airplanes, then our technology will certainly find success. That’s why I would prefer it for cars to start flying (laughs). There are many things now, like vehicles that only previously existed in the world of Sci-fi, that are no longer a thing of the future, and flying cars are now becoming more towards the realm of reality.

Automotive Material Strategic Planning Department as a “Jack-of-All-Trades?” Creating collaboration by laterally connecting people and organizations.

-I see, now I understand that just selling the products as they are isn’t enough. That is why the strategies of Mr. Tanaka’s department is necessary.

Correct. The Automotive Material Strategic Planning Department introduces Toray’s various materials for utilization in the automotive sector. Products such as fibers and resin, etc., will be coordinated by laterally connecting each group, in order to provide a one-stop proposal for clients. We will even consider pretty vague idea like “We don’t really know exactly, but we want to do ‘this’ type of thing.” We are like a “Jack-of-All-Trades,” we can arrange to discuss with the relevant resin departments for an inquiry, or consider teaming up with the carbon fiber department, in order to provide a proposal. In other words, our department does not exactly have a singular type of work that we have to engage in, rather, we can do anything, or in other words don’t really have to do anything to maintain the current status. But in the world of technology, you have to look ahead 5 or 10 years in the future when sowing the seeds of tomorrow. That is why our department exists, to incorporate different people in order to strategize for the future “right now.” We work in cooperation with people from different fields of work, not only from the technical side, but also from sales and other departments.

-It must be a pretty creative endeavor. In order to establish a team beyond particular department, you must require a thorough understanding of the company organization and technologies.

That is very true. We are a large company, and although I may know the members of my department that I directly interact with everyday, there are definitely more people in the company that I don’t know. Networking within a company is very important, that is why I often involve myself in research presentations and gatherings. Whenever I have a new inquiry from a client, whether or not I can immediately come up with the relevant person in charge becomes a pretty big indicator of the success later on. Although a technology-oriented company has the tendency to be more of a top-down organization, a neutral employee that could induce lateral cooperation will become more necessary in the future. This doesn’t mean that such person needs to know everything, all you have to do is bring a specialist that does when there is a project (laughs).

-Aside from in-house cooperation, are there any examples of collaboration beyond your own company and with other companies?

In the automotive industry, collaboration with other companies happens quite a lot. In our case, we often collaborate with components and molding manufacturers. It happens more or so when there is a part of product that requires solutions aside from what we could provide in-house. For example, if you are trying to combine metal and carbon fiber composite materials in order to reduce weight, you will need the technology to attach them together. Since we don’t have the know-how regarding adhesives, we would need to request an adhesive manufacturer to develop something. That is when a collaboration project will begin. Since the technology department often collaborates with other companies, we are open in regards to collaboration.

Strengthening Sales Activities utilizing BtoC Perspectives as Hints. Dissemination of Technology lies in “How you Communicate.”

-Do you have any new challenges you are taking part in?

Since we are a department that combines technologies to propose to our clients, I believe that “how you communicate” is crucial. Based on that idea, I am currently in the midst of trial and error to establish an environment that is easy to communicate, as well as how the communication should be done after the environment is organized.

-First of all, what do you mean when you say “establishing an environment that is easy to communicate?”

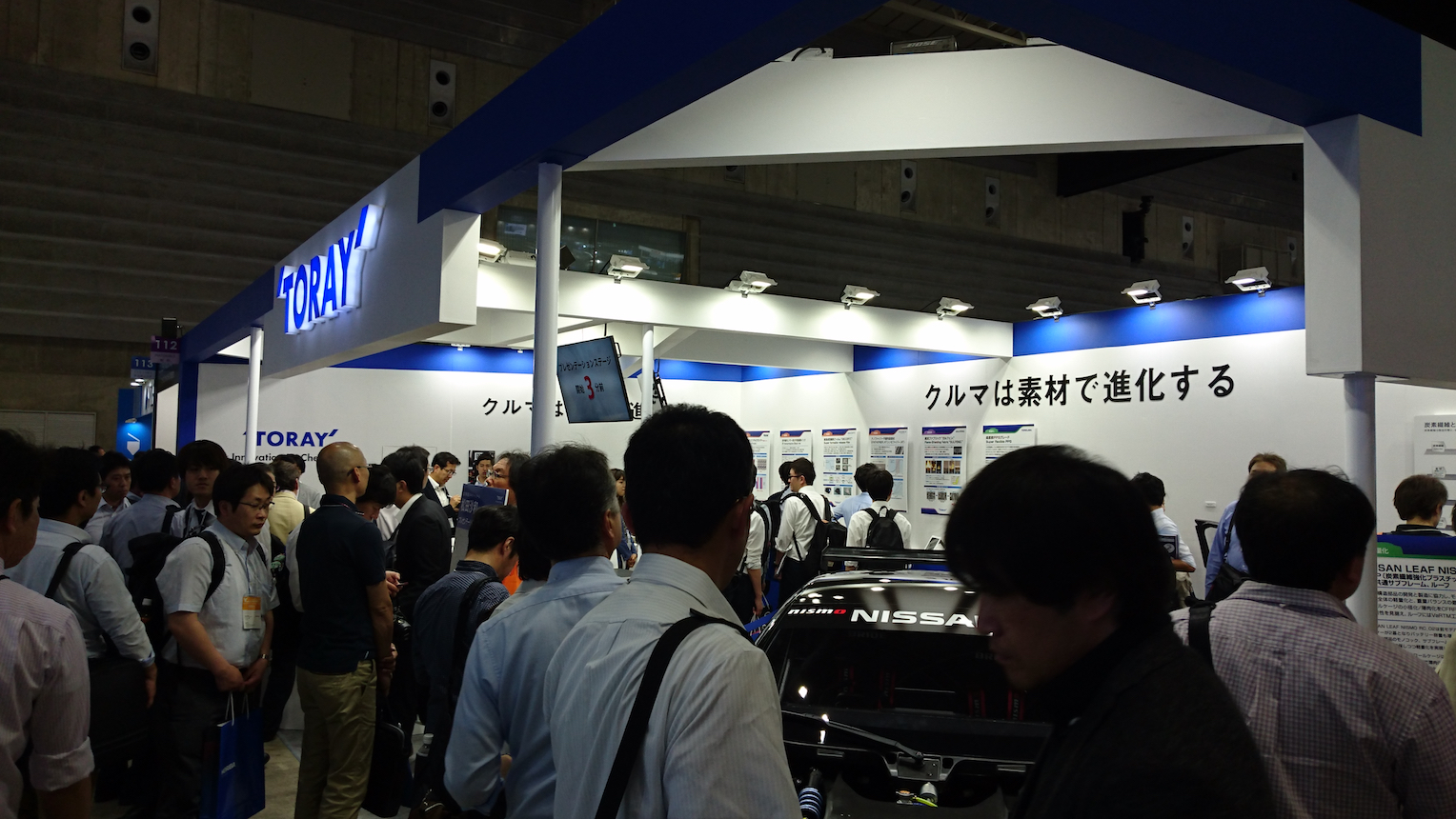

To be more specific, improving the marketing automation (hereinafter “MA”) or website of automotive-related materials. In regards to MA, our previous approaches, for better or worse, were more personal and strongly rooted in the “just go and talk to customer” kind of method. But with digitalization, our sales activity needed to be more efficient, and we have adopted it since about a year ago. For example, we were never able to efficiently utilize the business cards we received at exhibitions. But through the use of MA, we now send information that matches the interests of our potential customers. This has led to the optimization in our approach, in that upon seeing they have interest, we were able to make appointments for face-to-face visits. Although we have just recently started this approach, by having a department such as ours make the first contact, we hope for further incorporation into our company.

View from the “Automotive Engineering Exposition 2019 Yokohama” Exhibition

In addition, although we’ve always had an automotive-related website, it was far from what you would call a “great site.” Bus since there are clients who find us through the website, we wanted something where they could learn about Toray’s automotive-related materials in more detail. That is why we completely re-built our website. Obviously, you need more attractive contents to gain more viewers, so we plan to continue renewals and review, as we want the page to be the place where you can get the latest information through up-to-date news.

Toray’s AUTOMOTIVE SOLUTIONS website

https://www.automotive.toray/jp/

-So you update the platform in order to highlight the technology. How do you want to showcase Toray through the website, etc.?

We want to show viewers of the website about Toray’s vision and technology with specific visuals. If we could have the viewers hope that “cooperating with Toray will lead to new discoveries,” then I would be very happy. In addition, although maintaining an environment for communication by utilizing MA and maintaining a website is obviously important, I believe it should all be based on the idea to eventually have face-to-face communication with the client. Like the hope I want viewers to feel is something I would need to feel from people. From individual needs to ordinary trends, confirm what is real through face-to-face conversations with clients, not just through the media. It needs some persistent work.

-What kind of effort are you making for the other challenge, the “how to communicate” part?

When you are in sales for a long time, there are many moments where the way you communicate becomes very important. Since we are a technology-oriented company, we tend to bring the big data and boast that “with this technology the durability goes up XX%!” But from the client’s perspective, their response would be something like “so what?” (laughs) Instead, you have to show them that increasing the durability will widen the range of application so-and-so amount, and that is why it will be of use to them. But in order to do that, not only do we require the technological backing data, but also a proposal that goes a step ahead, something that will actually help the client understand.

-You are dealing with technology for BtoB market, but it actually sounds like your proposals are for BtoC. That is very interesting.

While the industry itself is completely different from that of B2C, I personally think it is very useful to refer BtoC strategy in terms of presentation. The technology-oriented company needs to slowly change too, we need to let our voice out in more easy-to-understand manner. When I first started working here, the company had more of a product-oriented mindset, with more of a focus on technology. But now, even the technology-oriented departments listen closely to clients, and are now more towards developing products while catering to their needs. That is why before we interact with our clients, we have close in-house communication and ask our technology departments for data that is easy for the client to understand. The days of just putting the technology out in the market and selling are over.

Once in a Century Period of Extraordinary Change. Gathering various industries to build the future of automobiles.

-What are your challenges going forward for the future?

As I mentioned previously, it is about adding more value to the materials and putting them out in the market. They say that the automotive industry right now is facing a once-in-a-century period of extraordinary change. Even in the media, keywords like CASE (an acronym of Connected, Autonomous, Shared & Services, Electric) are used whenever they talk about automobiles, but we are facing these changes from the perspective of raw materials. Under our slogan that “Cars Evolve by Raw Materials,” we hope to realize something that has never been done before using Toray’s value-added materials.

-What are the strengths of Toray that can be utilized for the future?

We have often been valued for our overall solutions as well as our technologies, and in fact, I believe those are the strengths that other companies cannot mimic. Toray began as a company that dealt with fibers, but we have expanded to feature a wide variety of fields including film, chemical, resin, electronic and information materials, pharmaceuticals and medical products, and water treatment and environment. So our strength is how we can utilize from our own variety of in-house technologies when we want to add value to a single material, Although the automotive related materials of Toray only account for 10% of the current sales figures, I believe we can expect to grow even more.

A partial lineup of Toray products. Aside from automotive materials, Toray handles a wide field of products, from fiber materials for clothing and medical devices

-Recently, we are seeing various mobility-related companies gathering up in Nihonbashi, with Denso relocating their Tokyo Office and Toyota’s TRI-AD* opening in Nihonbashi.

*A venture enterprise that aims in merchandizing the world’s cutting-edge research results at the Toyota Research Institute (TRI), where they are involved in the AI technology of autonomous cars.

Having companies in the same industry close by is a major plus. It is important to be able to have casual face-to-face communication with them without having to board a bullet train to travel long distances. At the same time, it is not as if we know each other on a personal level, so if there is a place for interaction that goes beyond companies, which would be great. Although I do not have an exact image of what to do with who, I would want to collaborate with an organization or company that has technology or function that we don’t have. As much as I can say that Toray covers a wide field of technologies, there is a limit to what a single company can do in terms of the scale and innovation of technology. That is why we want to connect with others with similar perspectives.

-By having technologies from various fields integrate into one, maybe an approach that will change the future of mobility might begin from Nihonbashi.

That would be delightful. Furthermore, as much as there are wide areas of technological possibilities, another trait of the mobility industry is that there are still many new issues that cannot be solved by technology, such as laws and regulations. So there is a need for organizations and companies from various industries to work together to bring about change to not only Japan, but worldwide as well. I would be delighted if we can utilize our know-how of strategic communication in such an endeavor.

Interview and Article: Minako Ushida (Konel) Photo: Daisuke Okamura

Toray Industries, Inc.

Founded in 1926 as a manufacturer of rayon thread and yarn, later expanding to four core technologies; organic synthetic chemistry, biotechnology, nanotechnology, and polymer chemistry. A basic materials manufacturer of cutting-edge, high value-added products based on these core technologies. Under the vision that "Materials have the power to fundamentally change society,” the company has internationally expanded to 26 countries and regions including Japan, and continues aiming towards a growth cycle of a global scale.